Exploring the New Energy Vehicle Battery Pack Seal Ring: A Small Component with a Powerful Protective Role

Publish Time: 2025-12-23

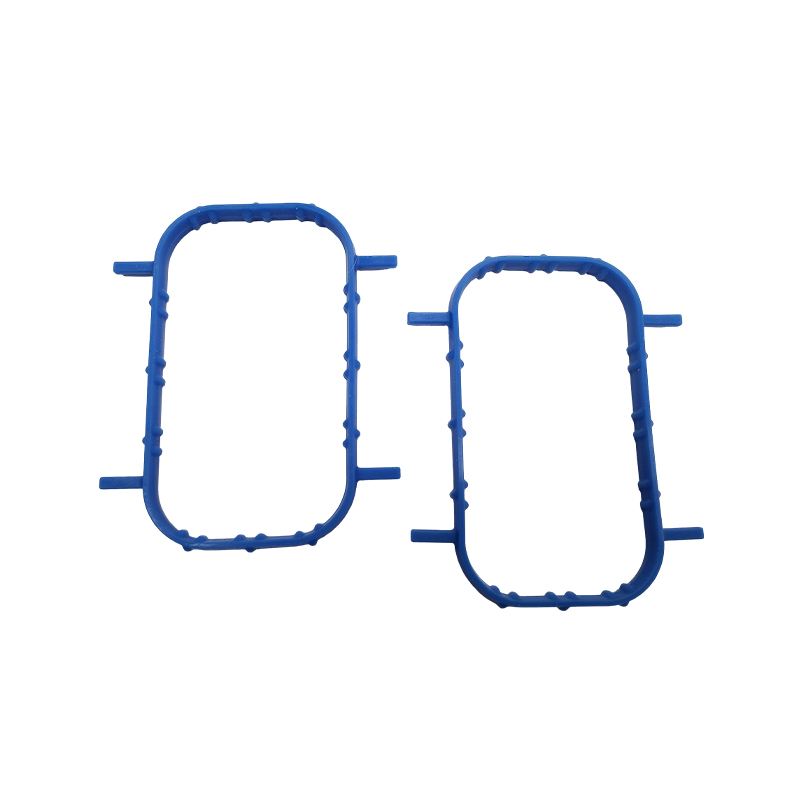

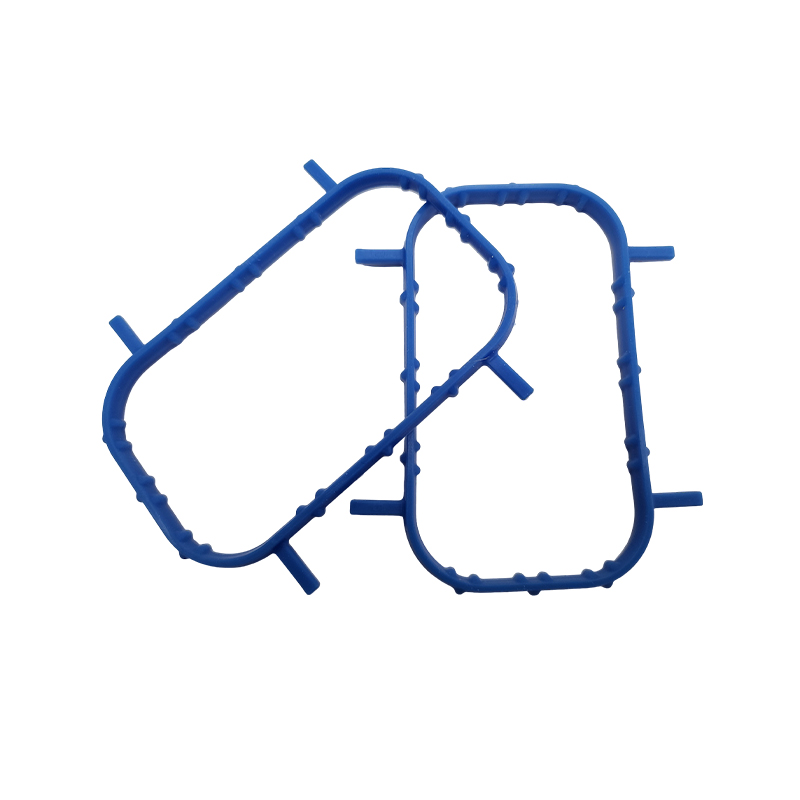

In today's rapidly developing new energy vehicle industry, the power battery, as the "heart" of the vehicle, directly determines the overall performance and user trust based on its safety, reliability, and durability. Within this vast and sophisticated energy system, there is a seemingly insignificant yet crucial "unsung hero"—the new energy vehicle battery pack seal ring. Despite its small size, it bears the critical mission of isolating the external environment and ensuring the stable operation of the internal battery cells. Thanks to its extremely high airtightness and liquid tightness, ultra-wide temperature range, excellent chemical corrosion resistance, good low-temperature elasticity, environmental friendliness, flame retardancy, and insulation, the new energy vehicle battery pack seal ring becomes the first line of defense protecting the "powerful energy" of new energy vehicles.1. Airtightness and Liquid Tightness: Building the First Barrier for Battery SafetyNew energy vehicle battery packs typically consist of hundreds or even thousands of cells, encapsulated in metal or composite material casings. If moisture, dust, or electrolyte leaks in or out, it can lead to insulation failure and performance degradation, or even short circuits, thermal runaway, and fire or explosion. The new energy vehicle battery pack seal ring must possess extremely high airtightness and liquid tightness to ensure complete isolation from external moisture, salt spray, oil, and internal electrolyte vapor throughout the battery pack's entire lifespan.The new energy vehicle battery pack seal ring uses special elastomer materials such as fluororubber, hydrogenated nitrile rubber, or silicone rubber, and achieves a seamless fit with the battery casing through precision molding. Even under long-term vibration, pressure fluctuations, or assembly tolerances, it maintains a stable seal, effectively preventing the hidden killer of "micro-leakage" and building an indestructible physical barrier for the battery system.2. Ultra-Wide Temperature Range: Effortlessly Handling Extreme Operating ConditionsThe operating environment of new energy vehicles is complex and highly variable, ranging from the frigid temperatures of -40°C in northern winters to the scorching temperatures exceeding 60°C in southern summers, and the internal temperatures soaring to 80–100°C during fast charging or high loads. The new energy vehicle battery pack seal ring must maintain stable function across this wide temperature range. High-quality battery pack seal rings can operate within a temperature range of **-55°C to +200°C**, far exceeding that of ordinary rubber products.Especially in low-temperature environments, many materials harden, become brittle, and lose elasticity, leading to seal failure. However, the new energy vehicle battery pack seal ring, specifically developed for new energy vehicles, ensures good elasticity and resilience even below -40°C through molecular structure optimization and plasticizer selection, preventing seal failure due to cold shrinkage and cracking. This "unaffected by cold or heat" characteristic allows the battery system to operate safely whether traversing snowfields or deserts.3. Chemical Corrosion Resistance: Resistant to Dual Erosion from Electrolyte and CoolantBattery packs not only contain organic solvent-based electrolytes but also often employ liquid cooling systems using glycol-based coolants for thermal management. These media have a strong swelling or degradation effect on ordinary rubber. If the seal ring material of a new energy vehicle battery pack is not properly selected, it is prone to expansion, hardening, and cracking, ultimately resulting in loss of sealing function.New energy vehicle battery pack seal rings are made of highly saturated main-chain fluororubber or perfluoroether rubber. Their high fluorine content and strong chemical bond energy give them excellent resistance to acids, alkalis, ketones, esters, alcohols, and various organic solvents. Even when immersed in electrolytes or coolants for extended periods, they maintain dimensional stability and mechanical properties, ensuring reliable sealing throughout the battery pack's 8-10 year service life and eliminating safety hazards caused by material aging.4. Environmentally Friendly, Non-Toxic, Flame-Retardant, and Insulating: Meeting Green Travel and Safety StandardsWith increasingly stringent global environmental regulations, the battery pack seal ring in new energy vehicles, as a component in close contact with the battery cell, must be made of environmentally friendly, non-toxic materials that release no volatile harmful substances to avoid polluting the internal battery environment or affecting the stability of electrochemical reactions.The battery pack seal ring in new energy vehicles also needs to possess excellent flame-retardant properties. Some high-end products achieve the UL94 V-0 flame-retardant standard by adding halogen-free flame retardants or using intrinsically flame-retardant materials. In the event of an external fire source or the initial stage of internal thermal runaway, it can effectively delay the spread of flames, buying valuable time for occupant escape and firefighting. Furthermore, good electrical insulation properties prevent the formation of conductive paths between the casing and internal high-voltage components, further enhancing the overall electrical safety level of the vehicle.

The battery pack seal ring in new energy vehicles bears the heavy responsibility of protecting the core energy system of new energy vehicles. Although it does not emit light or heat, it silently and resiliently resists wind and rain, isolates corrosion, blocks flames, and maintains insulation, building a safety barrier in the smallest details. It is these "invisible guardians" that ensure every acceleration and every long journey is built on reliability and peace of mind.