From Automotive to Industrial Equipment: High Temperature Braided Hoses That Withstand Extreme Heat

Publish Time: 2025-10-20

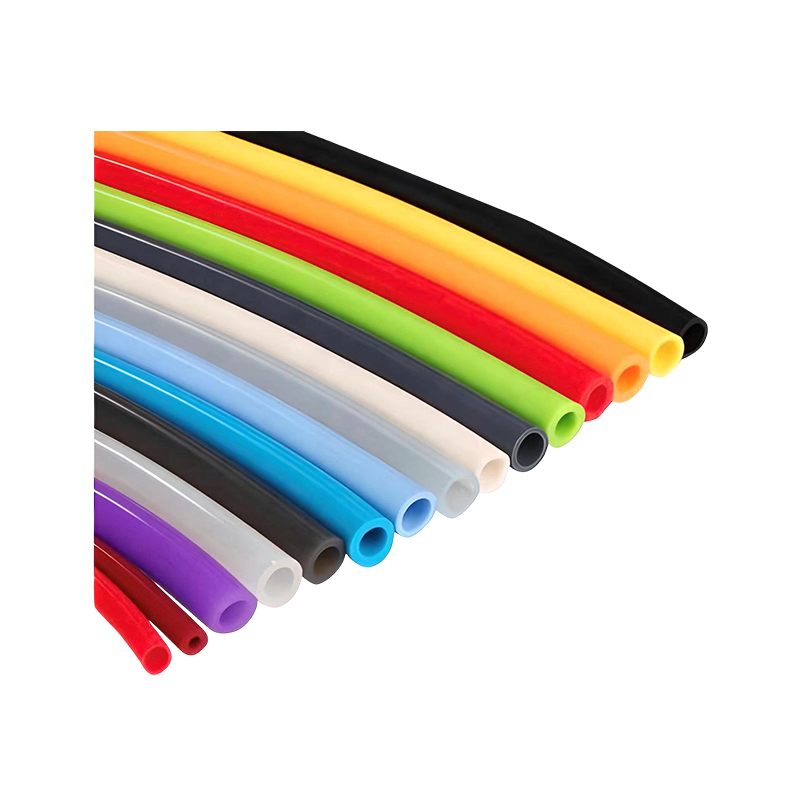

In modern industrial and automotive applications, hoses are no longer just simple connectors; they play a critical role in transporting fluids and gases while protecting systems under high-temperature, high-pressure, and complex operating conditions. High Temperature Braided Hoses (Silicone Hoses) are valued for their exceptional heat resistance, flexibility, and long-term stability. From automotive engine compartments to industrial high-temperature operations, these hoses provide reliable performance and ensure system safety.What is a High Temperature Braided Hose?A High Temperature Braided Hose is a hose made from high-performance silicone material, reinforced with braided fibers or metal wire layers. This braided structure allows the hose to withstand high temperatures while providing excellent pressure resistance and tensile strength. Silicone material itself has superior thermal stability, typically operating reliably in temperatures ranging from -60℃ to +250℃, without cracking, aging, or deformation. Compared to traditional rubber or plastic hoses, high temperature braided hoses offer enhanced reliability in extreme conditions and are ideal for continuous high-heat applications.Outstanding Heat ResistanceThe most notable feature of high temperature braided hoses is their exceptional heat resistance. Even in engine exhaust systems, high-temperature steam pipelines, or near industrial furnaces, these hoses maintain their flexibility and sealing performance. They do not soften, melt, or leak under extreme heat, ensuring safe transport of liquids and gases. Their heat resistance not only improves system reliability but also prolongs the lifespan of both the hose and the equipment, reducing maintenance and replacement costs in industrial and automotive applications.Braided Reinforcement for Pressure and Tensile StrengthHigh temperature braided hoses typically incorporate heat-resistant fibers or metal wires in a braided layer, significantly improving their pressure and tensile performance. The reinforced braid prevents expansion, bursting, or permanent deformation during high-pressure fluid transport and enhances bending flexibility. In high-pressure hydraulic systems, air conditioning circuits, or gas transfer applications, braided reinforcement ensures mechanical stability, making these hoses safe and reliable under demanding operational conditions.Extensive Applications in the Automotive IndustryIn the automotive sector, Silicone Hoses are widely used in engine cooling systems, turbochargers, air conditioning circuits, and exhaust auxiliary systems, where high temperature and pressure are common. These hoses withstand frequent temperature fluctuations and vibrations in engine compartments while maintaining excellent sealing and stability. The flexible design also simplifies installation and maintenance, improving overall vehicle reliability and making high temperature braided hoses indispensable components in automotive engineering.Core Role in Industrial EquipmentHigh temperature braided hoses also play a vital role in industrial equipment. They are essential in high-temperature steam pipelines, chemical transport systems, hydraulic devices, and heating furnaces, where hoses must endure continuous heat and chemical exposure while remaining flexible for installation and maintenance. The combination of silicone material and braided reinforcement allows the hoses to perform reliably under complex industrial conditions, reduce downtime, improve production efficiency, and provide a safe fluid transport solution for industrial operations.Perfect Balance of Flexibility and DurabilityBeyond heat and pressure resistance, high temperature braided hoses offer exceptional flexibility, allowing installation in tight or complex pipe layouts. This flexibility reduces stress on hose connections, minimizes the risk of leaks, and extends the service life of the hose. Whether in intricate automotive piping systems or multi-angle industrial equipment connections, high temperature braided hoses enable efficient installation and long-term stable operation, offering practical benefits for system maintenance and cost control.