What Are The Secrets Behind Customized Automotive Silicone Hoses In Combating High-Temperature, High-Pressure Corrosion?

Publish Time: 2025-09-08

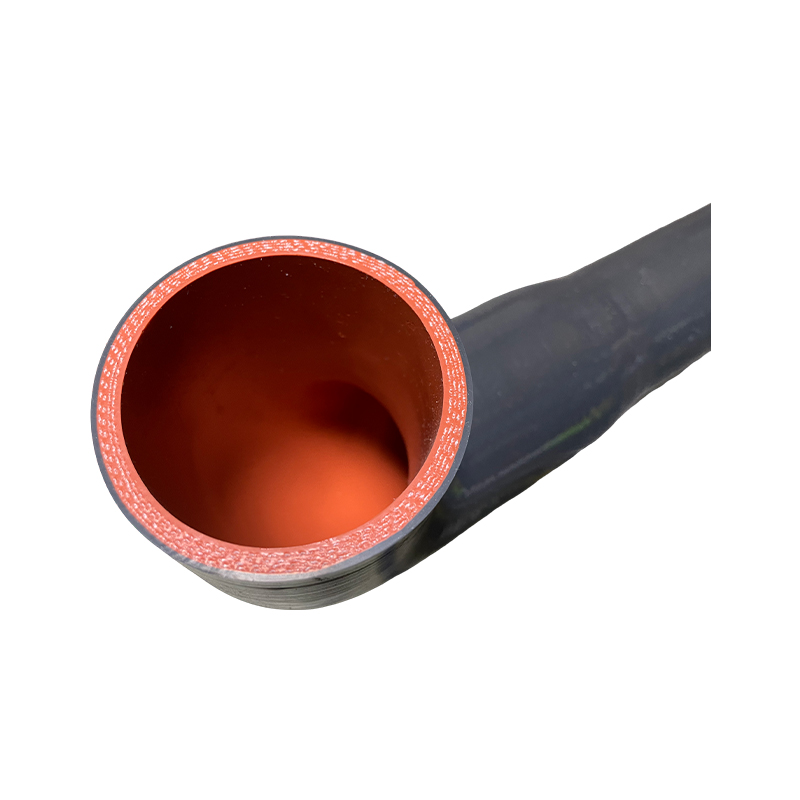

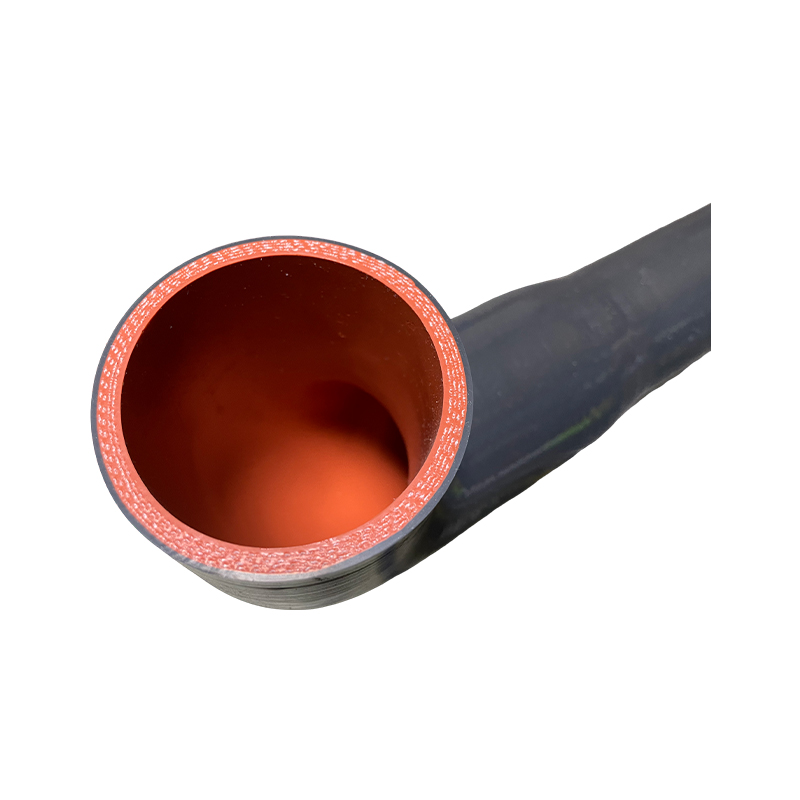

With the rapid development of the automotive industry, turbocharging has become a key means of improving engine performance. However, extreme operating conditions such as high temperature, high pressure, pulse fatigue, and chemical corrosion place stringent demands on turbochargers and their associated hoses. Traditional rubber materials are no longer able to meet the comprehensive durability, safety, and environmental requirements of modern vehicles. Silicone hoses, with their unique physical and chemical properties, are gradually becoming core components of automotive fluid transport systems. This article will delve into the innovative breakthroughs in customized automotive silicone hoses in the areas of high-temperature, high-pressure, pulse fatigue, and chemical corrosion resistance.1. High-temperature Resistance: Breaking the Limits of Traditional MaterialsWhen a turbocharger system is operating, compressed air temperatures can reach over 250°C. Ordinary rubber hoses will rapidly age and become brittle in such conditions. Silicone hoses, through optimized molecular structure design, utilize a high-purity silicone rubber base material and a special crosslinker to achieve a continuous operating temperature range of -60°C to 260°C, with short-term temperature resistance exceeding 300°C. For example, a customized project involved the introduction of a fumed silica reinforcement system and a platinum vulcanization process for connecting hoses for heavy-duty truck turbochargers and intercoolers. This resulted in the hose retaining over 85% of its tensile strength after 1,000 hours of continuous operation at 250°C, far exceeding industry standards.2. High-Pressure Design: Structural Reinforcement and Material InnovationTurbocharger systems can experience peak pressures exceeding 3.5 MPa, posing a significant challenge to the hose's pressure-bearing capacity. The customized solution utilizes a two-layer composite structure: an inner layer of highly tear-resistant silicone and an outer layer of braided aramid fiber reinforcement. Finite element analysis was used to optimize the braid angle and number of layers, enabling a specific turbocharger intake hose to maintain a tight seal at 4.0 MPa and a burst pressure exceeding 12 MPa. A variable-diameter bellows design developed by a company reduces local stress concentration by 40% while maintaining flexibility, significantly improving fatigue life under high-pressure conditions.3. Pulse Fatigue Resistance: Ensuring Reliability Under Dynamic Operating ConditionsFrequent engine start-stop pressure pulse cycles are a major cause of hose failure. During customized development, dynamic mechanical analysis (DMA) technology was introduced to precisely control the mobility of silicone molecular segments. The use of a silicon-nitrogen crosslinking system and nano-silica reinforcement ensures that the hose's volume change is controlled within ±3% after 100,000 pulse cycle tests. Optimizing the curvature radius and wall thickness distribution of the 90-degree elbow silicone hose used in a modified vehicle project has increased its pulse fatigue life from the industry average of 80,000 cycles to 150,000 cycles.4. Chemical Corrosion Resistance: Breakthroughs in Multi-Media CompatibilityTurbocharger systems contain media such as lubricating oil, coolant, and fuel vapor, posing a combined corrosion threat to hose materials. This customized solution utilizes a triple-layer protection system: a fluorocarbon resin surface coating creates an oleophobic layer, graphene is added to the middle layer for enhanced chemical stability, and boron nitride nanosheets are incorporated into the inner layer for enhanced oil resistance. Laboratory tests show that after immersion in SAE 5W-30 engine oil at 150°C for 1000 hours, the material exhibits a mass change of only 0.8% and a volume expansion of less than 2%, fully meeting the stringent requirements of turbocharger lubricating oil lines.5. Customized Production: Precision from Drawing to Finished ProductAdvanced CAD/CAM systems and rapid prototyping technologies enable precise manufacturing of complex silicone hoses. A digital production platform established by one company supports direct mold path generation from 3D models, shortening development cycles by 60%. For special-shaped pipe fittings, liquid silicone injection molding, combined with a multi-cavity mold design, enables the production of eight different specifications in a single shot, with dimensional accuracy reaching ±0.1mm. A variable-diameter turbocharger hose developed for a custom project utilizes a composite structure with an internal stainless steel spring frame and an outer silicone layer, enabling continuous adjustment of the tube diameter between 25 and 40mm to meet diverse engine compartment layout requirements.6. Application Cases: Performance Verification and Market AcceptanceIn a new energy commercial vehicle project, a custom-developed hydrogen fuel cell silicone hose successfully passed extreme tests, including low-temperature startup at -40°C and high-temperature operation at 120°C, achieving a hydrogen permeability of less than 1×10⁻⁸ Pa·m³/s. A turbocharger silicone hose used in a high-performance passenger car ran continuously for 500 hours without leaks during bench testing, contributing to a 15% increase in engine power. These cases demonstrate that customized silicone hoses have become a key component for improving the reliability of automotive powertrains.7. Intelligence and Sustainable DevelopmentAs the automotive industry transitions toward electrification and intelligent driving, silicone hoses are moving toward functional integration. A company has developed a smart sensor-integrated silicone hose that monitors temperature, pressure, and fluid composition in real time, with a data transmission error of less than 0.5%. Regarding sustainability, breakthroughs have been made in the development of bio-based silicone materials, replacing petroleum-based raw materials with plant-derived monomers, reducing the product's carbon footprint by 40%. These innovations will drive the expansion of customized silicone hose applications in new energy vehicles.